Danke für ihr interesse

auf der Logimat 2024

Sie wollen mehr Effizienz? Wir machen Ihr Lager zum Profit-Center – mit optimalen Prozessen von Pick bis Pack.

Willkommen bei Ix-tech

Ihr Intralogistik-Spezialist für Pick-By-Light und Assistenzsysteme

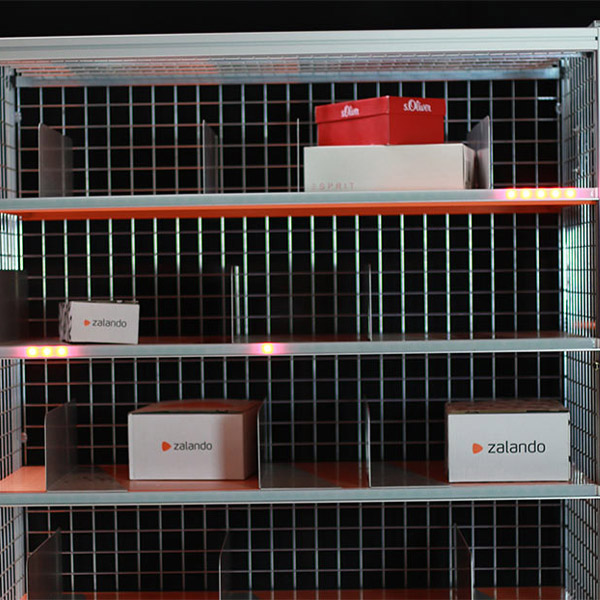

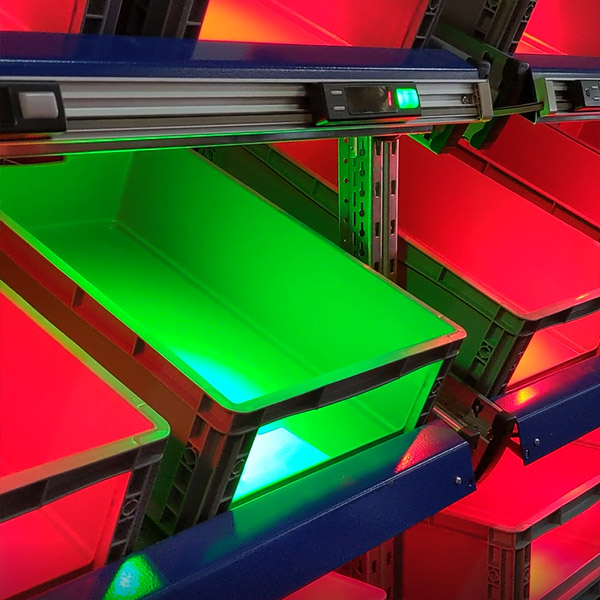

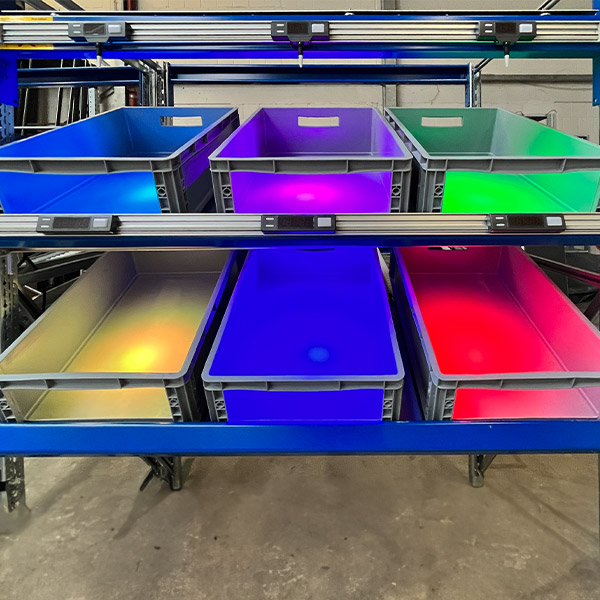

Die Suche nach den richtigen Produkten im Lager ist zeitintensiv und fehleranfällig. Pick-By-Light vereinfacht diesen Prozess mithilfe visueller Anzeigen wie Gangleuchten oder Lagerplatz-LEDs und führt die Mitarbeiter präzise durch das Lager.

Dabei erhält jeder Mitarbeiter eine eigene LED-Farbe und individuelle Anweisungen, womit auch parallele Kommissionierung problemlos möglich ist.

Entdecken Sie unser Spektrum an Pick-By-Light-Varianten, von einfacher Signalleuchte bis hin zur Displayanzeige und profitieren Sie von unseren auf Sie zugeschnittenen Assistenzsystemen.

lösungen & Assistenzen

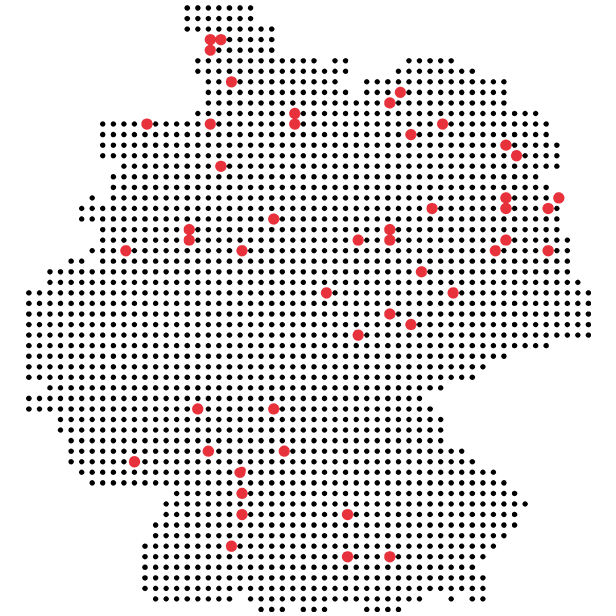

Die Wurzeln im Saarland - in der Welt zuhause

Egal ob E-Commerce, Logistik oder Fullfillment – überzeugen Sie sich von uns und entdecken sie deutschlandweit unsere zufriedenen Referenzkunden.

Was wir Ihnen bieten

UNSERE LEISTUNGEN

Logistiklösungen

Planen. Gestalten. Umsetzen.

Wir machen Ihr Anliegen zu unserem Eigenen. Zielgerichtet und individuell starten wir jedes Projekt gemeinsam mit Ihnen und betreuen unsere Kunden von der Problemstellung bis hin zur fertigen Lösung. Wir stellen den Mitarbeiter in den Mittelpunkt und automatisieren und optimieren Prozesse mit Hilfe modernster Technologien und jahrelanger Erfahrung.

Prozessoptimierung

Egal ob Versandhandel oder Werkerführungsysteme in der Industrie – Ihre Prozesse werden mit Hilfe unserer Lösungen vereinfacht, beschleunigt und sichergestellt. Als eigenständige Insellösung oder komplexe Fertigungslinien – die Anwendungsbereiche unserer Lösungen sind nahezu unbegrenzt.

NEWS

-

LogiMAT 202418. Dezember 2023/0 Comments

-

Handgeräte für Weihnachten leihen25. Oktober 2023/

-

MOTEK 20234. Oktober 2023/